Téciman performs the reverse engineering of dies for an automotive leader, through the cooperation of internal teams Metrology and Design, offering a complete solution.

The client needs to make modifications to some dies, but doesn't have the drawings to do so. They come to us because of our comprehensive service capabilities.

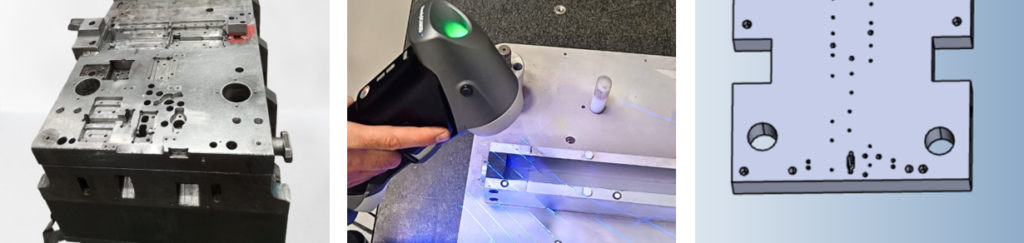

The project: Reverse Engineering of dies

Phase 1: Measurement and 3D Scanning

The project begins with the data collection of the dies in situ, traveling to the client's facilities. It is mainly carried out by 3D scanning, although other measuring equipment is also required depending on the part. Specifically, a Creaform portable 3D scanner is used.

Phase 2: 3D Modeling

Once the polygonal model is obtained (the skin or surface of the piece), our design team generates the solid 3D models through design software SolidWorks and VX Model.

Result: Precise CAD models

Through this technology we deliver to the client precise CAD models, despite not having the original plans. This allows me to improve the existing design instead of creating one from scratch, which involves saving time and costs.

Collaboration between the 3D Metrology and Design areas of Téciman

Collaboration between the areas of Design and Metrology allows us to offer a comprehensive and highly efficient service, key in projects where time and precision are critical.

This integration ensures seamless communication, avoids rework, and accelerates delivery times, as the 3D models generated from the scan are interpreted and transformed directly into ready-to-use design solutions.

Thanks to this collaborative approach, we achieved reduce costs, minimize errors and offer the customer an agile, precise experience that is fully adapted to their technical needs.

For more information about our capabilities call us at 947 20 91 41 or send us an email to teciman@teciman.com. Follow us on LinkedIn to find out all the news.