Maintenance

Preventive or Corrective Maintenance

In the face of all types of breakdowns, both hardware and software.

Comprehensive support of Coordinate Measuring Machines (CMM), regardless of the software.

Retrofit or update from MMC, both hardware and software and with a 1-year warranty.

Know How

- Checking mechanical elements: review and adjustment of the lateral guide of the X axis, condition of the bearings, drives, belts, counterweight cable and other mechanical elements of the equipment that may need to be adjusted and/or replaced.

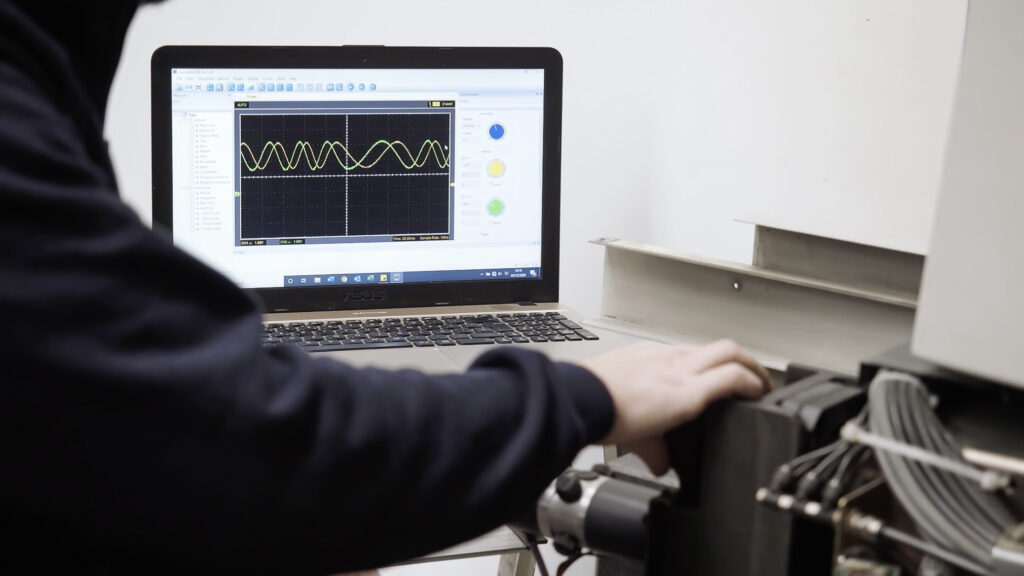

- Checking attached elements: of the electrical circuit (power supply, voltages,…) and the security system. Review of the pneumatic system (depending on equipment) Checking the state of the circuit, the slippage of the equipment, the cleanliness of the air and the state of the filters.

- Computing environment verification of peripheral connections.

- Leveling the table, bench or main cart, It influences the straightness in the X axis, in Y and Z directions and the angularities around the X and Y (pitch and roll).

- Cleaning the reading system: review and cleaning of tapes and adjustment of reading heads.

- Review of electronic regulation of the numerical command.

- Displacement Review of the equipment on the 3 axles, raceways and possible friction and/or wear.

- Fast and flexible response to all types of breakdowns

- Team with experience in the repair of machines of different brands

- Wide availability of spare parts discontinued by the manufacturer

- Multiannual Maintenance and Calibration Plan

Geometric Fit

Phases

- Mechanical adjustment: It makes the machine more stable over time and minimizes its drift.

- Software Adjustment: By acting on the software adjustment matrix, optimal precision is achieved.

The machine must be mechanically adjusted prior to making the adjustment by software. Otherwise, the imbalances will increase and the parameters entered in the software adjustment will be erroneous. This is especially noticeable in arm-type coordinate measuring machines.

Machine must be mechanically adjusted before adjustment is made by software. Otherwise, the imbalances will increase and the parameters entered in the software adjustment will be erroneous. This is especially noticeable in arm-type coordinate measuring machines.

Types of Geometric Adjustment

- STANDARD: The 6 basic parameters that affect the geometry of the machine (positionings and perpendicularities) are corrected. Generally recommended option.

- COMPLETE: The 21/23 total parameters are corrected (positionings, perpendicularities, linearities, rotations). For machines that have not been geometrically corrected for a long time, machines with very low specifications or after moving equipment.

All adjustments are mechanical and/or software with linearity and perpendicularity coefficients, or up to 23 parameters; depending on the desired options.

In lateral or arm machines, a mechanical adjustment of the bed, table or main carriage is made. The mechanical correction of the straightnesses in the X, Y, Z axes and the perpendicularities are necessary to achieve good precision and therefore the best machine uncertainty result.

If you have any questions about the adjustment option to hire, We analyze your case and determine the type of adjustment necessary.

We also offer the possibility of performing a simplified calibration to know the real state of the equipment before geometric adjustment.

Transfers of Three-Dimensional Machines

Move a Coordinate Measuring Machine (MMC) involves careful work: disassembly, fixing, packaging, handling, transport, unpacking, installation, commissioning, adjustment and calibration.

Téciman is capable of carrying out all these operations offering a full service of moving their machines.