In the field of industrial metrology, relying exclusively on manufacturers for the maintenance and repair of Coordinate Measuring Machines (CMMs) can lead to high costs and long downtime.

Teciman offers a comprehensive solution that allows repair, upgrade and calibrate any CMM, regardless of age, brand, model or software, giving companies complete independence from the manufacturer.

5 Advantages of Comprehensive MMC Repair

- Manufacturer independence

Thanks to technologies like Chameleon electronics, it's possible to maintain existing software and measurement programs, eliminating the need to purchase new licenses or change software.

- Measurement programs are maintained

Regardless of any repairs or upgrades, current measurement programs are maintained to avoid disrupting workshop operations.

- Universal compatibility

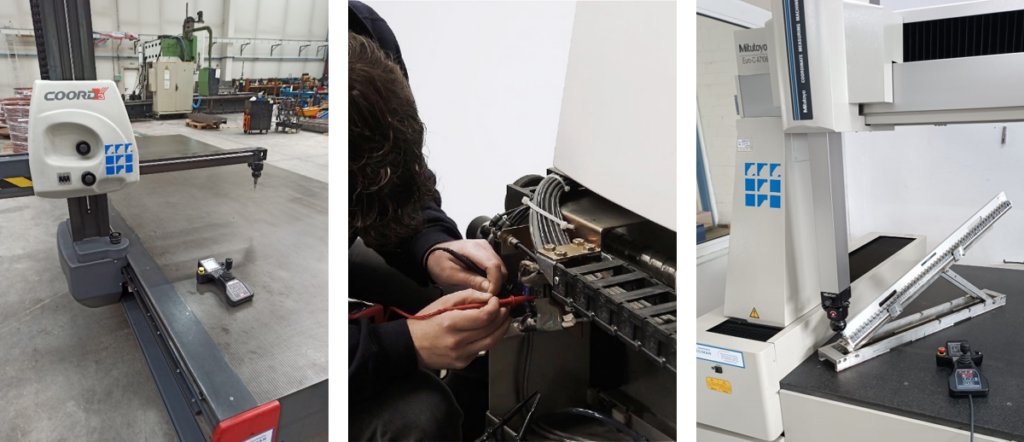

Téciman has experience in repairing machines of different brands and models, including Zeiss, Hexagon, Mitutoyo, Coord3, among others, guaranteeing solutions adapted to each team.

- Spare parts availability

A comprehensive catalog of spare parts, including those discontinued by manufacturers, ensures the operational continuity of the MMCs.

- Reduction of costs and times

By avoiding manufacturer lock-in, costs associated with licensing and services, as well as wait times for repairs, are significantly reduced.

Complete repair process

Téciman's comprehensive service covers all the stages necessary to ensure the optimal functioning of the MMCs.

-

Diagnosis and evaluation: Identification of both hardware and software faults, determining the necessary corrective actions.

-

Adjustment and maintenance: Inspection and adjustment of mechanical, electrical, and pneumatic components, ensuring equipment precision and reliability.

-

Repair and upgrade / retrofit: Repair of elements, including updating probing systems and software, extending the life of the machine.

-

ENAC Accredited Calibration: Calibration is carried out in accordance with the standards of the National Accreditation Entity (ENAC), ensuring the traceability and accuracy of measurements.

When is a retrofit performed?

He retrofit It is the ideal solution when a Coordinate Measuring Machine (CMM) needs to be reinvented, whether due to obsolescence, lack of spare parts or technological limitations.

ANDThis process allows you to completely modernize the machine, regardless of its age, brand or original software, without the need to purchase new equipment.

Benefits of retrofitting

One of the main advantages of retrofitting is the possibility of maintain existing measurement programs, thanks to solutions such as Chameleon electronics, which allows new electronics to be adapted to current software without the need to change licenses or interfaces.

Furthermore, retrofitting allows the machine to be customized to the customer's specific needs, incorporating new sensor technologies, probing systems, and cutting-edge software.

In short, retrofitting offers an efficient and cost-effective alternative to extending the lifespan of CMMs, improving their performance, and adapting them to current production and quality requirements, without relying on the original manufacturer.

With this comprehensive approach, Téciman not only restores the functionality of CMMs but also improves their performance, adapting them to current production and quality control needs. By eliminating manufacturer dependency, Companies gain in autonomy, efficiency and competitiveness in the market.

For more information about our capabilities repair, maintenance and calibration of three-dimensional machines Call us at 947 20 91 41 or send us an email to teciman@teciman.com. Follow us on LinkedIn to find out all the news.