Teciman certifies the dimensional specifications of a prototype wind turbine piece before proceeding to take the series.

The company, dedicated to the casting of aluminum parts, requires a third measurement report. It is requested by your client after manufacturing and measuring the piece. The document fulfills the objective of guaranteeing the dimensional specifications of the end client from a neutral perspective.

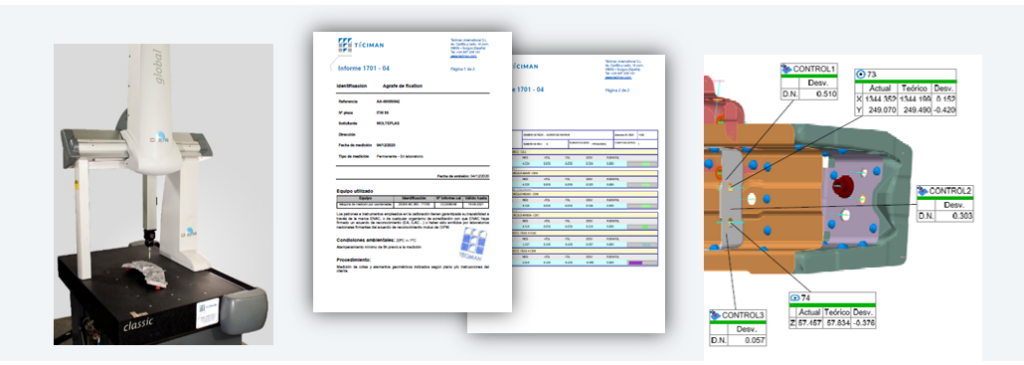

In this third report, The metrologists of Téciman They measure the geometric elements (support planes, fastening holes, etc.) and confirm the measurements provided by our client. Both companies were satisfied with the results, so the order for the series was launched. This neutral document prevents any future problems due to incompatibilities in the assembly of the parts.

Téciman uses a Three-dimensional measuring machine of high precision to verify the measurements; since our client previously measured with an articulated arm. It is true that given the characteristics of the cast material, an articulated arm with a probe is sufficient for the specific specifications required.

At Téciman, we have various measuring methods and we have total flexibility to travel to the client's home or carry out the measurements in our own laboratories. In this specific case, the work was carried out in the Burgos laboratory, but we are also in Valladolid, Vitoria-Gasteiz...