Integrated Systems

Integrated systems are automated quality control inspection solutions for large series, large pieces, integration into the production line...

High repeatability comparison system

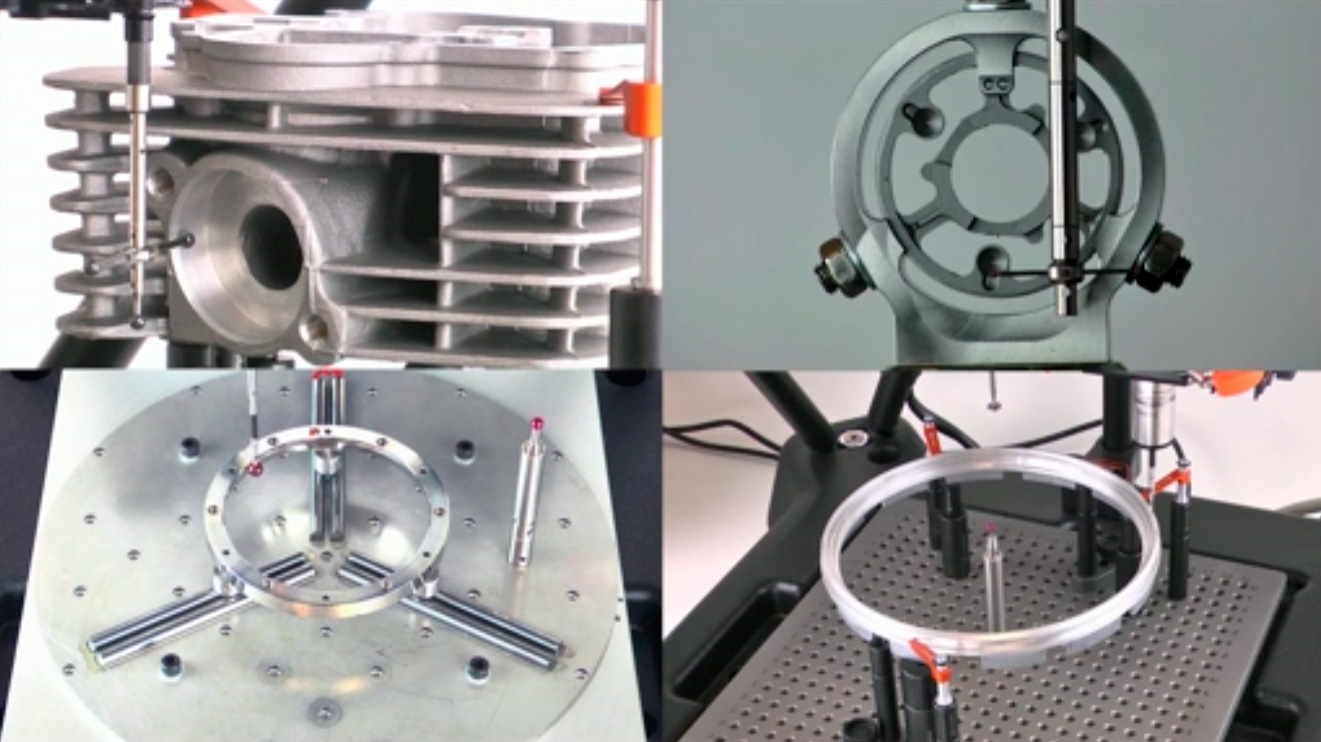

Equator™

The Equator gauge allows the manufacturing process to be controlled using a comparison system of high repeatability, very versatile and reprogrammable for use in the workshop.

- Reduces part rejection

- Reduce bottlenecks

- Low maintenance cost

- Easy automation

- Thermally insensitive

Automation and Robotics Unit

Téciman performs the complete integration into production lines, including all associated engineering: design and development, programming, installation and commissioning.

In the integration process, the unit Automation and Robotics de Téciman takes care of absolutely everything: solving how to automatically power the system, designing and manufacturing the necessary tools, programming the PLC, robot and the Equator itself, and finally assembling and installing on the client's production line, with the corresponding tests and validations.

Automated QC Inspection Solutions

CUBE-R

Coordinate Measuring Machine 3D scanning key in hand, accurate and fast for online inspection.

- High productivity

- Complete turnkey solution

- Smaller factory space

MetraSCAN3D-R

A powerful robot mounted optical scanner that can be integrated into car projectsfactory tint. Fast, reliable, and versatile solution, maximizing the production cycle and performance

- Multitask

- Really accurate

- Automatic calibration

Three-Dimensional Measuring Machine for workshop

RUN

Designed for the production environment (workshop or manufacturing plant).

Measurements: RUN 444, RUN 765

- Operation without compromised air

- Equipped with linear motors

- Fixed bridge structure and mobile table

- Fully integrable into production lines

- Intuitive user interface

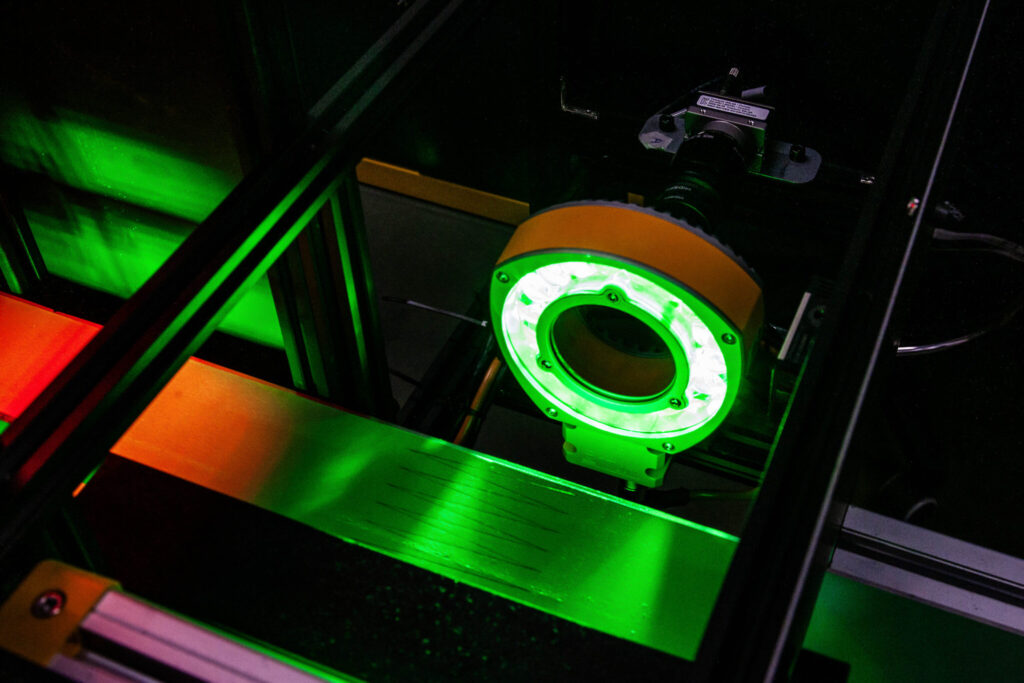

Machine Vision

We implement machine vision technology to provide machines with the ability to view, interpret and process images of the real world, allowing them to make decisions and execute tasks autonomously.

- Quality control automation

- Optimization of production processes

Our systems integrate cameras, sensors and image processing algorithms to obtain accurate visual information.

Examples

- Quality Inspection in Production Lines.

- Piece counting and defect detection.

- AI-based product classification.

- Standard Process Control.

- Image analysis in industrial environments.