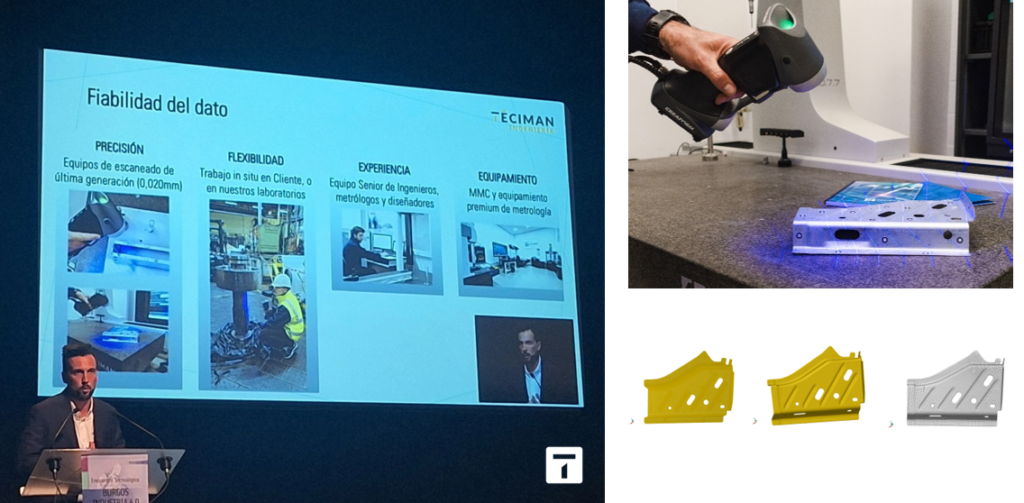

You can now watch the full presentation "Reverse Engineering: Applications and Use Cases in Automotive" by our colleague Sergio González Jiménez, Director of Engineering at Téciman Engineering, within the Industrial Track 2025 Technical Conferences of the Burgos Industry 4.0 Technology Meeting (#DIHBU).

🎥 Watch it here 👉 https://youtu.be/7Ja3G0CYfnc

What is discussed in the presentation?

-

What is reverse engineering?: definition, context and why it has become a key tool in industrial environments.

-

When and why to apply it: The most common scenarios in the automotive industry where the lack or inadequacy of CAD blocks the workflow are explained.

-

Real use cases: Examples of applications are shown in automotive sector clients, both in manufacturing and maintenance, where time savings and precision have been decisive.

-

Concrete benefits: from reducing time to improving the quality of parts or components and optimizing processes.

-

Good practices and recommendations: What to consider when implementing a reverse engineering project, how to choose the right tools, and how to combine it with other 4.0 processes.

Who is it aimed at?

-

Design and maintenance engineers working in the automotive industry who need to manage parts without CAD or with incomplete documentation.

-

Manufacturing managers looking to optimize time, reduce rework, and improve efficiency.

-

Engineering directors interested in incorporating advanced technologies into the production cycle.

-

Consultants and service companies that provide technical support in industrial environments.

Reverse engineering: precision and speed when time is money

In an industrial environment where time is money, the reverse engineering It has become an essential tool for reacting quickly to unforeseen events.

When a CAD model is not available or the plans are incomplete, this technology allows digitally reconstruct an existing part or assembly through the 3D scanningFrom the resulting point cloud, a precise CAD model is generated that can be modified, reproduced, or integrated into the manufacturing process.

Thanks to this, the teams of maintenance, design and production they can reduce downtime, improve quality and maintain the operational continuity without relying on prior documentation.

Don't miss the full presentation here: https://youtu.be/7Ja3G0CYfnc

And if you'd like to learn more about how we apply reverse engineering to our projects, don't hesitate to contact us! Call us at 947 20 91 41 or send us an email to teciman@teciman.com. Follow us on LinkedIn to find out all the news.